The astronauts on the International Space Station have access to a slew of state-of-the-art scientific instruments and cutting-edge technology, from hand-held DNA sequencers to robot assistants to even a 3D printer.

But when it comes to plain old 2D printing, the emphasis, as of late, has been on the “old.” [Space Station’s 3D Printer Makes Wrench From ‘Beamed Up’ Design]

“If you think about it in terms of its age, the printer can vote,” said Stephen Hunter, NASA’s manager for space station computer resources at Johnson Space Center in Houston, Texas. “And that is just the time we’ve had it on orbit. If you add in the years of development, it’s probably closer to 21, so the Epson printer can probably step up to any bar and order a drink.”

Since the first crew moved on board the orbiting laboratory in November 2000, the space station has been equipped with the same model of inkjet printer: the Epson 800. But after almost two decades, even with swapping out units every 18 months or so, keeping the printers up and running has become a real issue.

“I use that analogy because while the printers have worked well, the maintenance for them has just become too hard for us now,” said Hunter in an interview with collectSPACE. “So the decision became either we’re going to upgrade our printing capability or we just weren’t going to print anymore.”

Not printing was not an option.

Epson passed on NASA’s invitation to help develop a new printer, so NASA found a new commercial partner in HP.

All in one

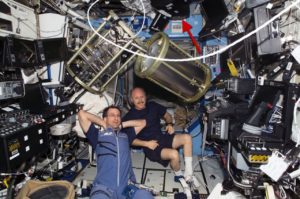

The astronauts use the printers on the space station for the same reasons people on Earth use them in offices and at home. The crews print out work documents as well as personal files.

“Letters from home, photographs and training materials are the types of things the crews print,” said Hunter. “If you think about how much you print at home, or how much you print in your office environment, the same kind of thing applies in space, except that there are some critical things the crew has to print.”

While the astronauts have ample access to laptop and tablet computers, there are just some things they cannot keep in electronic format only. For example, were the space station to suddenly lose power or if the crew had to evacuate the outpost in an emergency, they could not rely on there being an available digital screen or the time needed to access their procedures. So hard copies are a must.

The rare contingency aside though, there is also the human factor.

“There’s something very human and psychological about the feel of paper,” Hunter explained. “You get things that are very personal to the crew — letters from home, pictures. There are some who have used the printers to make keepsakes to bring home. One crew member used the printers to print out their expedition patch on a special type of paper from their home country and used that as souvenirs.”

The space station’s printing needs put the orbiting outpost into a unique category, said Ronald Stephens, the R&D manager for HP Specialty Printing Systems.

“For the astronauts, the space station is really a combined environment,” he said. “It looks like an enterprise environment, where you have ‘corporate’ NASA on the ground changing procedures and sending up materials to be printed remotely, and we at HP work in those type of environments quite often.”

“It is also clearly an office and laboratory environment. You’ve got astronauts doing research, printing reports, graphs, other engineering and science documents.”

“And then it is also their home — their family sends an email or a photo,” added Stephens. “I think the challenge is that the space station is really a combination of all of the different types of segments that printers go into. It is that all in one.”

Off the shelf

The astronauts’ printing needs may indeed be all in one, but the printer they use would be better if if it was not, said Hunter. When the Epson 800 first went into use aboard the space station, many commercial printers did just and only that, print.

“We wanted to stay with using a commercial off-the-shelf printer and then modify it for our needs,” said Hunter. “But as you can no longer find a printer that just prints, we had to take an all-in-one style printer and disable some of its functions.”

No one is sending faxes to the space station. And while it might be nice to be able to scan and copy documents in orbit, the printer parts needed to enable that are a problem for NASA.

“We needed to remove the glass out of the printer, because if that were to shatter or break we’d have a safety issue. It saves weight as well,” said Hunter.

After doing a market study of the available home and office printers, NASA found an HP model that could be modified to fit its needs.

“They were interested in our OfficeJet 5740 printer and working with us to figure out what would be the best way to replace the technology that they currently have on the space station,” Stephens told collectSPACE in an interview.

Out of the box, the OfficeJet 5740 could probably work if hung on a wall or even a ceiling here on Earth. But to print in microgravity, modifications were needed.

Off the planet

To figure out what worked and what did not in its printer, HP came up with test and mounting fixtures to mount the OfficeJet upside down, sideways and at 45-degree angles.

“At many of the orientations, yes, the standard OfficeJet is able to accommodate,” stated Stephens. “The biggest challenge from a zero-gravity standpoint was paper management.”

As it happens, the off-the-shelf 5740 comes standard with a small arm that lowers down on the paper entering the printer, and a roller that lifts the top sheet to feed it in “a perfect design for a zero-gravity paper pick,” said Stephens.

So going in, modifications were only needed to keep the paper stack in place. But what goes in must come out.

“You have to think about how you capture the paper in a microgravity environment. If you do not have some type of restraint, you end up with confetti shooting out of the printer,” Hunter said.

“Obviously that would be unacceptable,” said Stephens. “We used 3D printing and came up with an output tray design that uses some flexible fingers to help redirect the orientation of the paper as it’s coming out of the printer — basically to knock it down and simulate that action that gravity would pull the paper. And then we have got a unique bale arm that’s able to catch and stop the paper and keep it in place.”

There were other, more minor changes made as result of microgravity, which were also solved with printed parts. For example, the carriage that moves the printhead from side to side normally hangs on a rod.

“Here [on Earth], we count on gravity to rotate it so that it hangs down in its correct position. We realized that would be a challenge in zero gravity and so we used 3D printing to shim that down and force it into the needed orientation,” said Stephens. [How a Robot Arm in Space Inspired Tech for Surgery on Earth]

Keeping ink in and fire out

NASA’s requirements for the modified printer weren’t only that it needed to work in microgravity. It also had to function safely aboard the space station.

For example, because the printers will be mounted in areas where astronauts and cosmonauts could bump into them accidentally while floating through the modules, there could not be any sharp edges.

And because fire precautions are paramount on orbit, NASA required that the new printer be made from fire-safe materials. So, HP re-molded all of its printer’s plastic parts from fire-retardant alternatives.

And then there was the ink.

Early on, NASA ruled out launching laser printers. The laser, itself, was considered a safety risk, the printers required too much power and the fine powder inside the drum of a laser jet would be a “huge contaminant” if it got out. So then it became a question of how to keep the ink from an inkjet printer contained.

HP’s OfficeJet cartridges do not rely on gravity to work. Unlike the example of the space pen, which required a pressurized ink cartridge to replace the pull of gravity, the HP printer cartridges use thermal forces to create a bubble inside of the nozzle, and that bubble is what ejects the ink out.

“And to prevent the ink from just drooling out of the printhead, this family of inkjet printers uses foam inside the print cartridge and the capillary force of the liquid in the foam is what gives us the back pressure in the ink cartridge so the ink doesn’t ooze out,” explained Stephens. “So, we were not required to make any changes to the ink or the ink cartridges for it to work.”

That does not mean, though, that droplets of ink do not sometimes pool inside the printer. On Earth, those drops fall and evaporate over time. But in space, where the droplets won’t ever drop, there is concern of ink escaping the printer.

“If the ink were to escape, it could contaminate science payloads or even be a risk to the crew with ingestion,” said Hunter.

That resulted in HP having to do “quite a bit” of work to redesign the interior of the printer, such as filling open areas with absorbent materials, Stephens said.

“We also used a special tape to cover all the seams of the case parts, so that if in the very unlikely event ink were to somehow get out of the inside of the printer, it will be unable to get out of the printer into the environment,” he said.

Mission ‘NV’

Taking all of the changes into account, the modified-for-orbit OfficeJet 5740 differs from an off-the-shelf printer by only about 10 percent. But, as it turns out, that was enough to warrant a new name.

Borrowing from another of its product lines, HP named its space station printer the “HP ENVY ISS” printer.

The first HP Envy ISS is launching on SpaceX’s CRS-14 Dragon cargo spacecraft and is expected to be installed by the station’s crew for a qualification run in May.

“We’re deploying this as a technology demonstration before we can do the full out replacement,” said Hunter. “I’m expecting, based on the amount of testing that we have done for this, that this printer will work flawlessly.”

Assuming everything does work, the Envy ISS will replace the two Epson printers — one in the U.S. and one in the Russian segment — on board the space station. NASA intends for the Envy ISS to be in use through the end of the space station, whenever that may be. (At present, the station’s partners have agreed to extend to at least 2024.)

“For the ground, we bought of the 50 of the unmodified, right-off-the-shelf printers to provide our training areas and have spares, and we purchased 50 printers to be modified for flight,” said Hunter, noting the quantities were based on HP production runs.

“We’re very excited about it because this is the first new printer for the ISS since its inception 20 years ago,” he said.

For its part, HP is prepared to support the Envy ISS printer on the space station, a project it has dubbed “Mission NV.”

“It’s been a blast to work with the NASA team very closely,” said Stephens. “It has certainly been the most exciting project I have worked on in my many years with HP.”