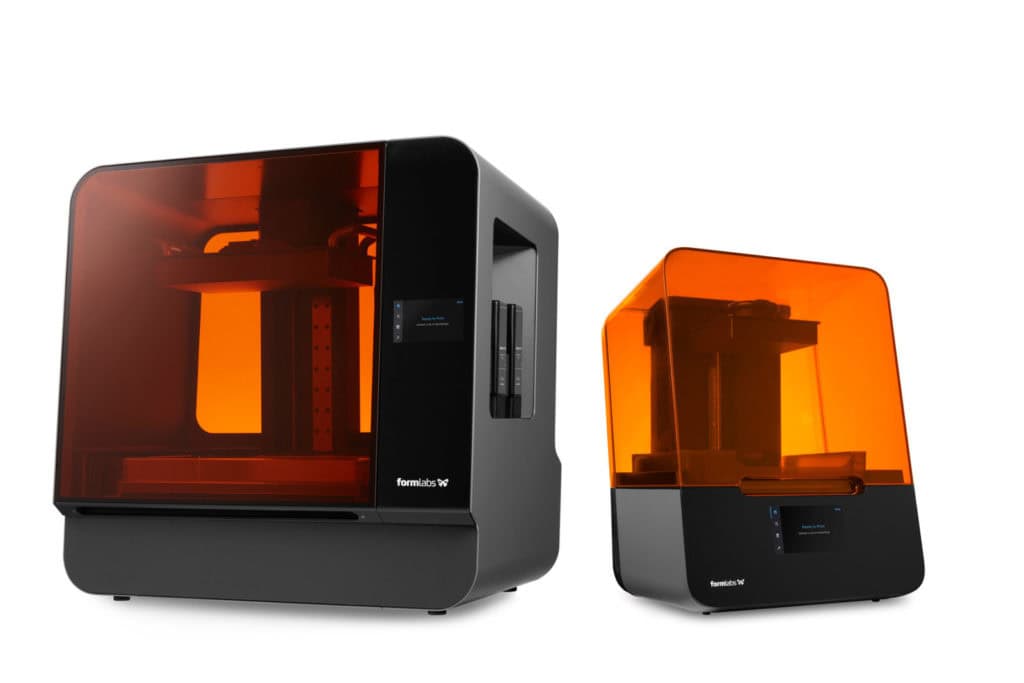

The Form 3 and Form 3L are the future of commercial 3D printing.

Formlabs’ 3D-printing technology is now being used to make razor handles, movie props and even false teeth. It makes sense, then, that the products coming out of its printers need to be as smooth as possible to avoid the need for extra finishing. That’s the key benefit that the company is touting as it launches two new models, the Form 3 and Form 3L.

CEO Max Lobovsky says that the company has “completely re-engineered approach to resin 3D printing,” thanks to a new process dubbed Low Force Stereolithography. Benefits of the process include more detailed models, thanks to a new flexible tank that can adapt to the build’s geography. Not to mention “flawless prints,” with easier clean-up, while the hardware is both more reliable and faster, too.

Of course, these aren’t devices that any mere mortal can grab from their local bodega, with the cheapest Form 3 costing $3,499 and the 3L starting at $9,999. The smaller of the two models will begin shipping in June, while the larger will arrive at some point towards the end of the year. Formlabs’ older, Form 2 printers, will get a little cheaper as a consequence, with prices starting at $2,850.